From 2014 on, Green Vinyl Records (Symcon) has been developing a new production process to manufacture vinyl records without chlorides. In this short interview, we ask Harm Theunisse, director of Symcon, to tell us more about this innovative development.

How far are you with the new product and its process?

We expect to have the technical sound aspects of the new vinyl records ready May 3 at Making Vinyl in Berlin.

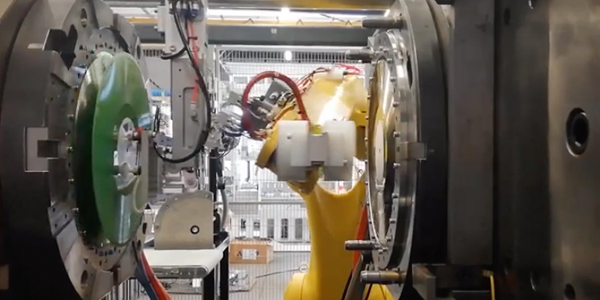

We will also present the innovative manufacturing process and attachment of the paper label on the records. The new procedure is less labor-intensive and will result in less waste when the printing of a label goes wrong.

How has the market reacted so far?

We have received many positive reactions. Most people really want to see and ‘taste’ the new LPs.

In the past 40 years, practically nothing has changed in the manner that vinyl records are produced. But now many innovative techniques and this manufacturing process can produce a better sound and a more sustainable stable product.

We are very much aware of the fact that our new vinyl records must be compatible with the old record players that people have stored away in the attic.

People who have listened and tested our Green Vinyl Records are enthusiastic about the quality. In fact, the sound is better than on conventional records and the and the signal-to-noise ratio (background noise) on our newly produced LPs are more silent than the traditional process.

Furthermore, Green Vinyl’s scratch resistance is four times better than records using the regular manufacturing method.

Who in the record business has already reviewed your product?

Harry Coster (recipient of a Grammy Award and four Edison Awards for music production) was enthusiastic about Green Vinyl. And there are some other highly renowned people from the business who are interested, but for the moment we must keep this under wraps.

When do you think the new Green Vinyl Records are ready for the market?

We expect to have everything ready within five months.

How do you anticipate the market for Green Vinyl roll out?

We expect not to produce the new vinyl records ourselves. We will lease our production lines and services to others. Symcon is originally a trade and service company and seeks to associate with forward-thinking, established record producers and production companies. Both Symcon and the partners who developed the Green Vinyl record process agree that everybody should stick to their core business instead of competing with one another. It is the best solution for the entire commercial chain within the record manufacturing industry, especially because our production lines are cheaper (less energy costs, no waste, no chlorides) and faster. Last but not least, with minimal labor costs!

More information

http://greenvinylrecords.com/

https://www.youtube.com/watch?v=r1lGSSw0Y4g